Product Details

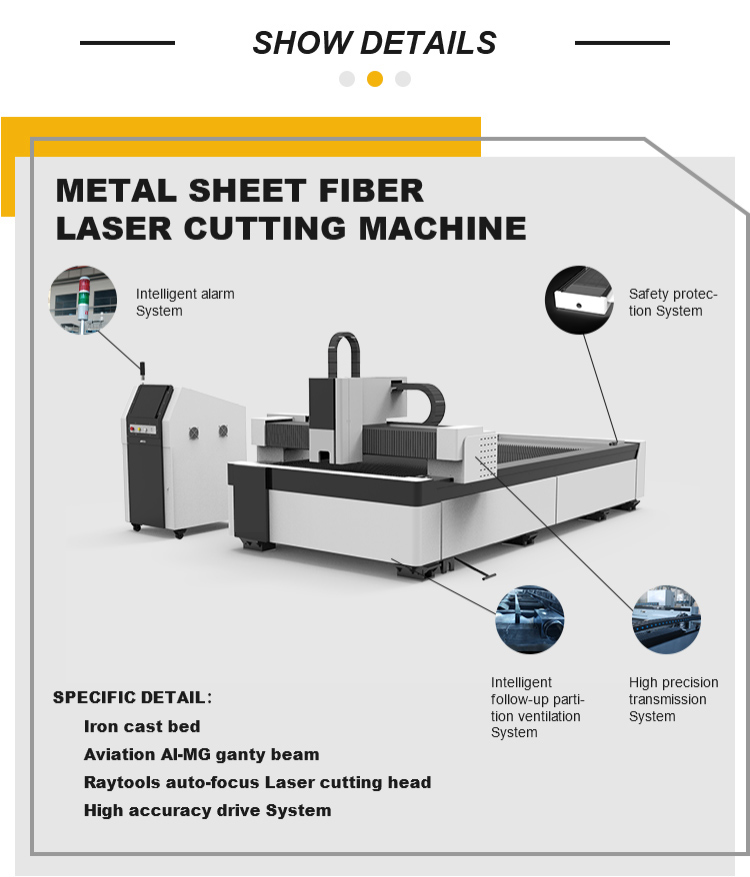

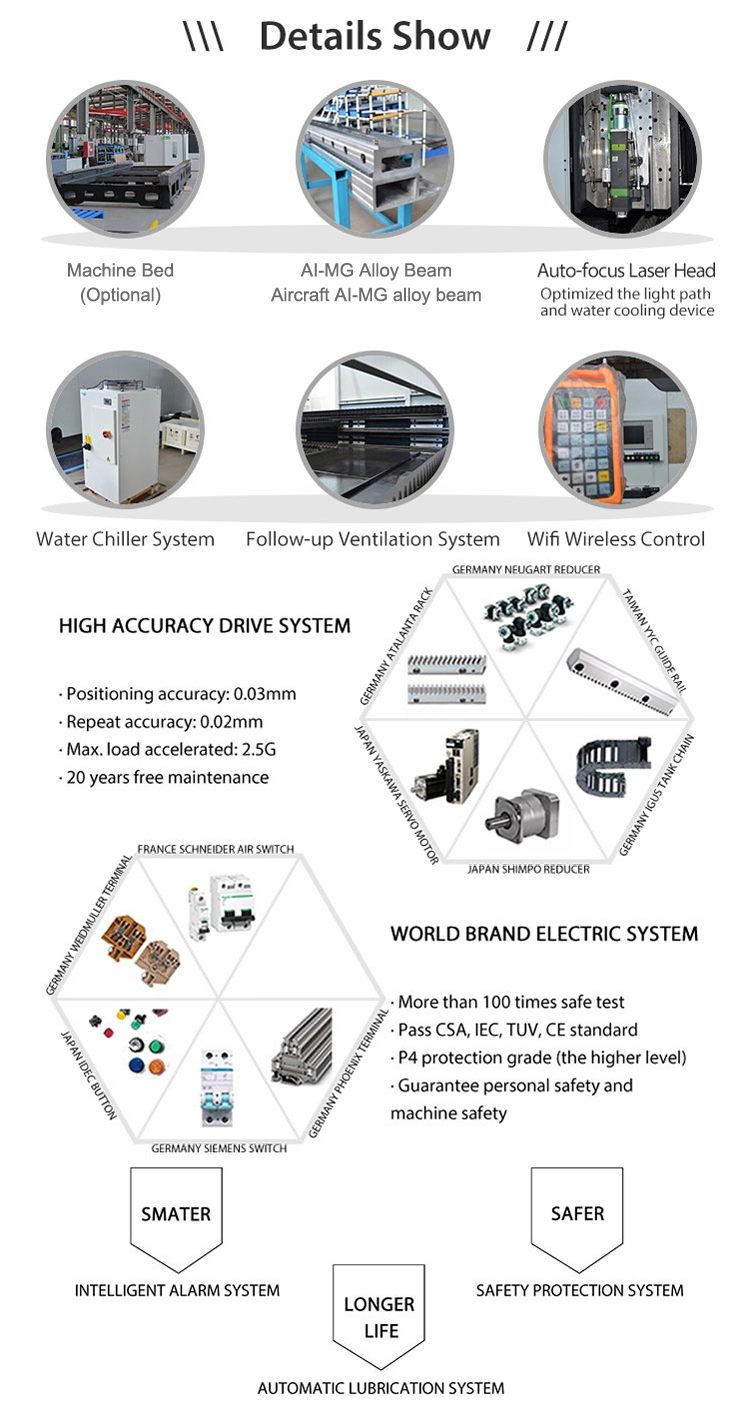

As a new machining method, laser cutting has the advantages of high cutting precision, fast operation speed, easy operation and high degree of automation.

This series is the most cost-effective one suitable for the cutting of medium and thin sheet metal. This machine is designed for used in compact or limited space, with the auxiliary feeding mechanism and the cantilever feeding system which can largely improve the customer's sheet metal cutting efficiency in a limited space.

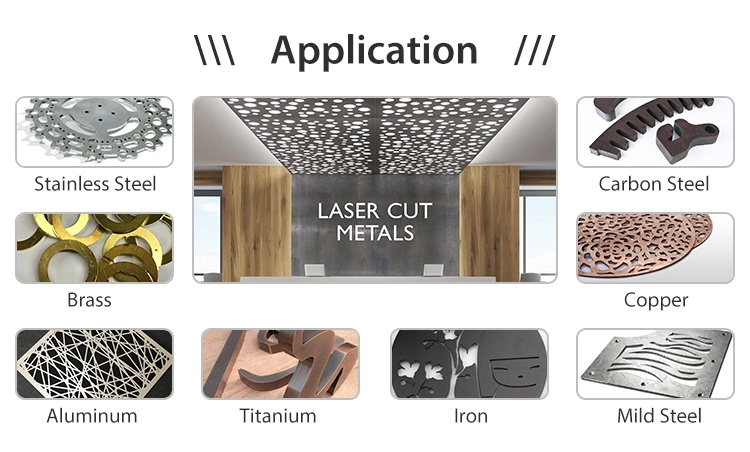

Suitable for production line transformation, small-scale sheet metal cutting and small site environment. Widely used in sheet metal processing, advertising signs, kitchenware, hardware, lighting hardware, auto parts, saw blades, glasses, mechanical parts and other metal industry production.

| Model | Cutting Area | Laser Power | Bed |

| F3015 | 3020*1520 | 1000W 1500W 2000W 3000W 4000W 6000W 8000W |

Welded Bed Cast Iron Bed Marble Bed |

| F4015 | 4020*1520 | ||

| F4020 | 4020*2050 | ||

| F6020 | 6020*2020 | ||

| F6025 | 6020*2520 |

Fiber laser cutting machine is good at processing on common metal items in daily life such as advertising metal letter, kitchenware, environmental protection equipment. Laser cutting machines are widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries. Stainless steel, carbon steel, alloy steel, copper, brass, silicon steel, galvanized steel sheet, nickel titanium alloy, Inconel, titanium alloy, etc.

Export standard for Metal Fiber Laser Cutting Machine Laser Cutter:

1-Scratch resistant and anti-static with professional packing film;

2-Anticollision for whole machine with special mould;

3-Waterproof and waterproof with tarpaulin material.

Approved Vendor for International Giants SIEMENS

Member of CLA (China Laser Association)

CNGC (China Weapon Industry Corporation) Laser Equipment Supplier

Annual total export exceeds 15 million US dollars

Professional provider of Wisdom solutions in China.

FAQ

Q1: What can I get the available machine if I don't know anything about laser?

BEIKE Laser will provide the customized application solution for your requirements, just tell us your material, material thickness, worktable and e-mail or WhatsApp ID.

Q2: How to choose the machine that I want?

BEIKE Laser provides information consulting about product, price, technology and industry solutions for customers at any time via network, telephone, email and door to door.

Q3: When I got this machine, but I don’t know how to use it. What should I do?

BEIKE Laser provides free installation and training for users’ technicians, ensures that users can get familiar with operation methods and put machines into use as soon as possible.

Q4: If some problems happen to this machine, what should I do?

BEIKE Laser provides 3 years warranty and lifetime maintenance. Free repair for mechanical failure and parts damage (no human factors and force majeure factors) under warranty (replacement parts except wearing parts are provided by BEIKE Laser are free of charge). Charging at cost when out of warranty.

Related Products

Inquiry