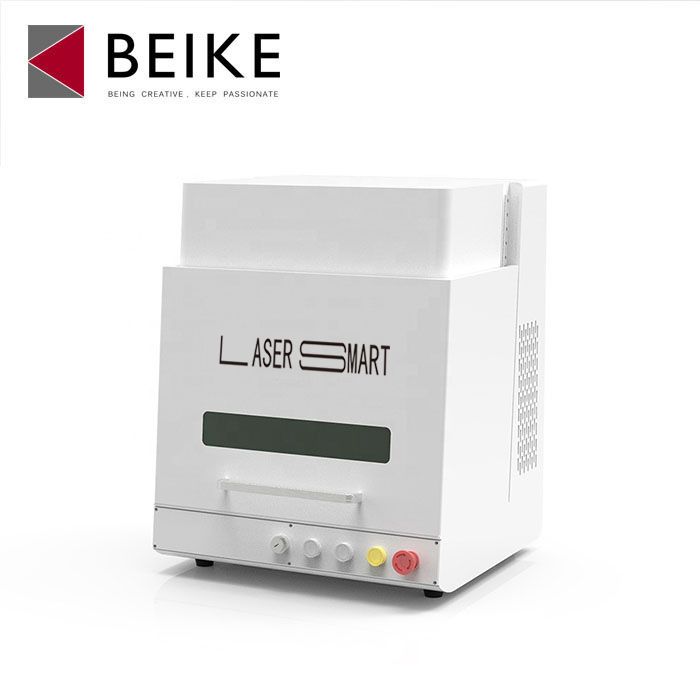

Desktop fiber laser marker use the fiber laser output laser equipped with high-scanning galvanometer system to achieve a permanent mark on the surface of a variety of materials printed.

1. Visualization of tracing information

2. Thoroughly prevent the goods

3. Complete flow scheme control of production

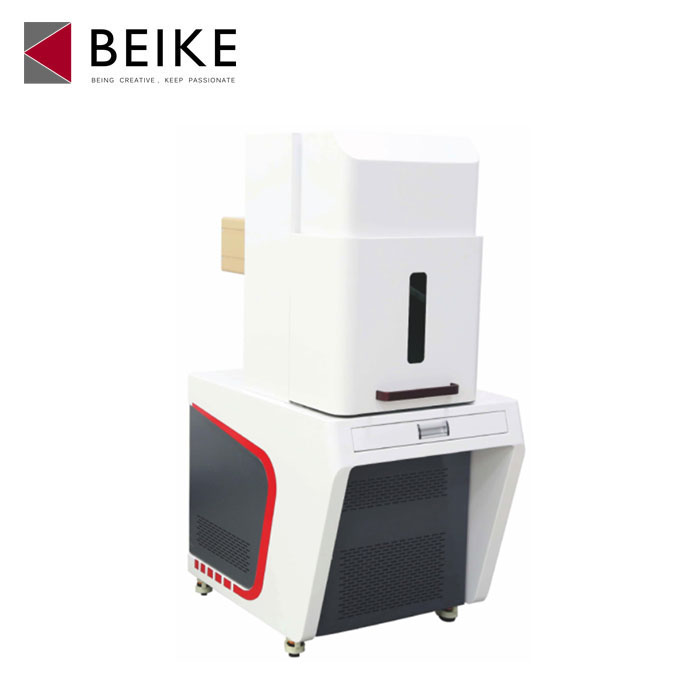

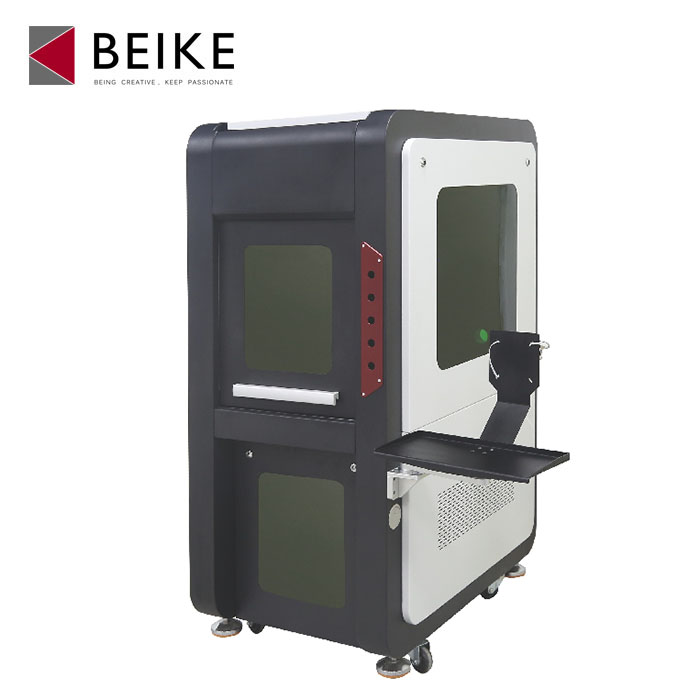

The Intelligent Laser Marking Machine BK-I are the protected fiber laser marking machine, equipped with OD5+ laser protective glass and all cover cabinet, designed according to the European machinery standard and safety requirement, the most popular laser marking machine in USA, European and Australia marketing.

The big table size fiber laser marking machine BK-B is designed for high-volume marking processing. It can be widely used on various metals and some non-metal surfaces to produce permanent marks.

The online fiber laser marking machine can make dot matrix or scribbling laser encoding with high quality on fast moving products and meet the demands of all kinds of production lines.

The online CO2 laser marking system series integrate advanced galvanometer laser marking technology with imported RF excited sealed CO2 laser. Combining laser technology with production line, it can mark on rapid moving products.

BEIKE desktop CO2 laser marking machine can process most nonmetal materials, such as painting acrylic, density board, plastic, acrylic, rubber, bamboo, marble, painting glass, wood, leather, TPU and other nonmetal materials.

BEIKE BK-SC series handle laser marking machine is mainly used for marking to big size and heavy weight products which are not easy and convenient to remove and carry.

Green Laser Marker Series is designed to mark highly reflective materials or highly sensitive substrates like silicon wafers with ease and precision. They operate in the visible light spectrum at 532 NM (Green).

UV laser marking machine was developed using 355nm UV laser. The machine uses third-order cavity frequency multiplication technology compared with infrared laser, 355 UV light focusing spot is extremely small, can be Reducing the mechanical deformation of the material to a great extent and having a small effect on the processing heat.

Enclosed Design

Exchange Platform

Welded Bed / Whole Cast Iron Bed / Manu – Marble Bed

IPG or Raycus Laser Source

Laser Power: 1000W – 8000W

BEKKE MOPA Laser Marking Can Achieve The Color Printing On Stainless Steel Materials.

BEIKE series 3D laser marking machine is made with imported core parts and equipped with high speed and high precision 3D galvanometer, can use laser to print on any curved surface parts with high precision.

The CCD laser marking machine is improved from the traditional laser marking machine via equipping the “eyes and brain”for the machine to achieve the ability of finding the targeted marking position and angle on the parts and print automatically, this make the laser marking machine can “see” and “think”.

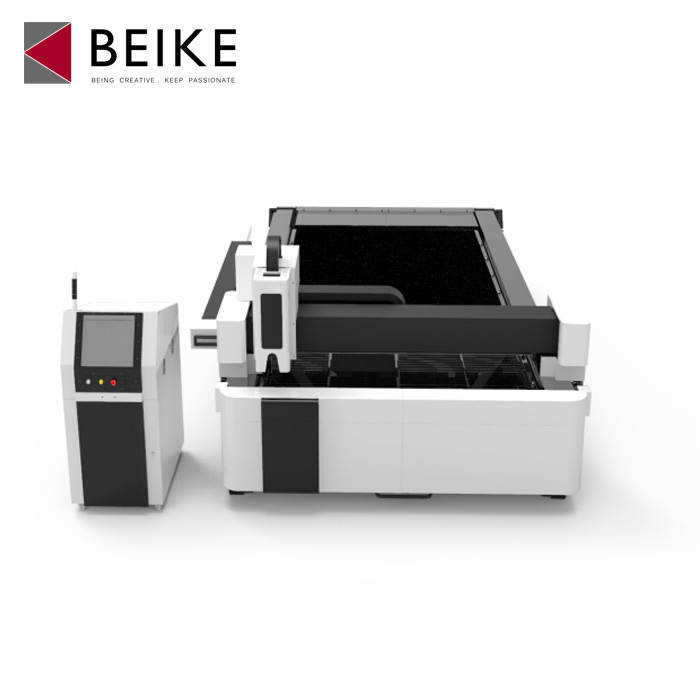

Single Platform

Welded Bed / Whole Cast Iron Bed / Manu – Marble Bed

IPG or Raycus Laser Source

Laser Power: 1000W – 8000W

CLEAN LASER provides surface preparation technology that’s both efficient and remarkably versatile for a growing list of industrial applications. Whether the surface is metallic, plastic, ceramics, glass, stone or concrete, the results speak for themselves.

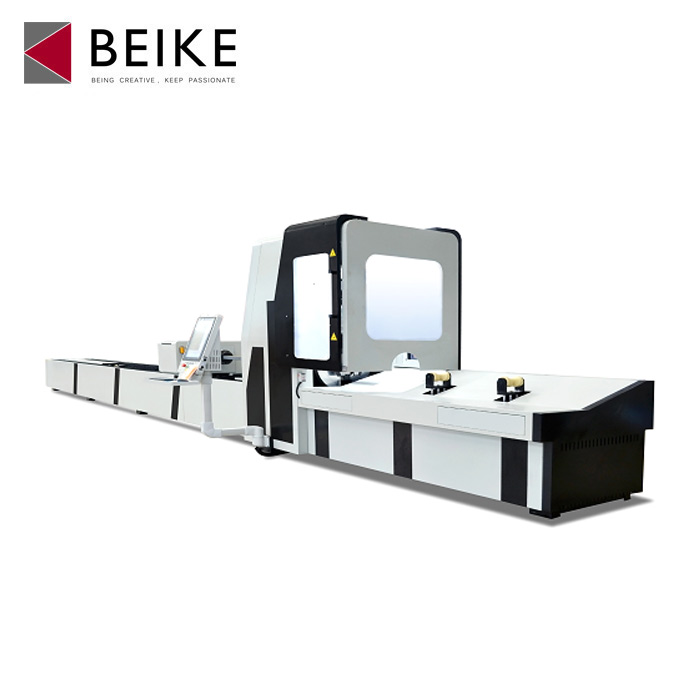

For Tube Laser Cutting Use

Welded Bed / Whole Cast Iron Bed / Manu – Marble Bed

IPG or Raycus Laser Source

Laser Power: 1000W – 6000W

Laser Cutting For 20-200mm Round Tube & 20-220mm Diagonal Length Square Tube

Cutting Length: From 6M To 12M

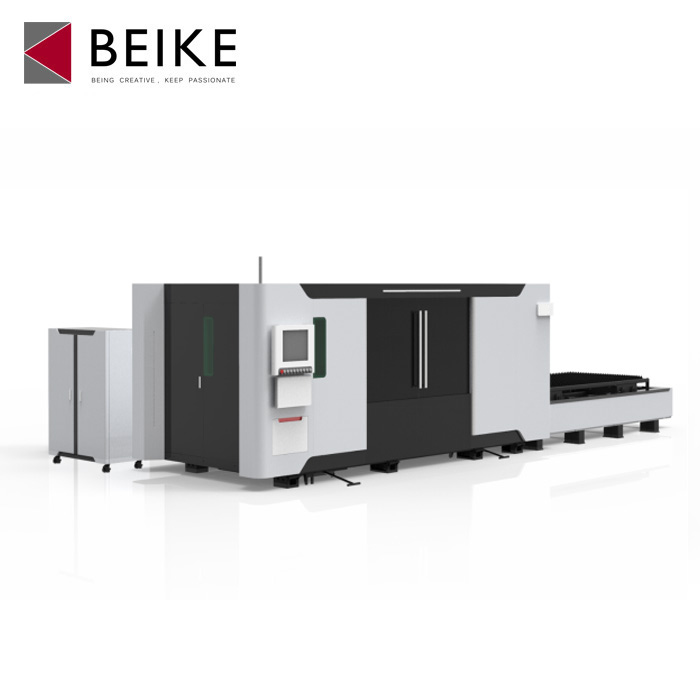

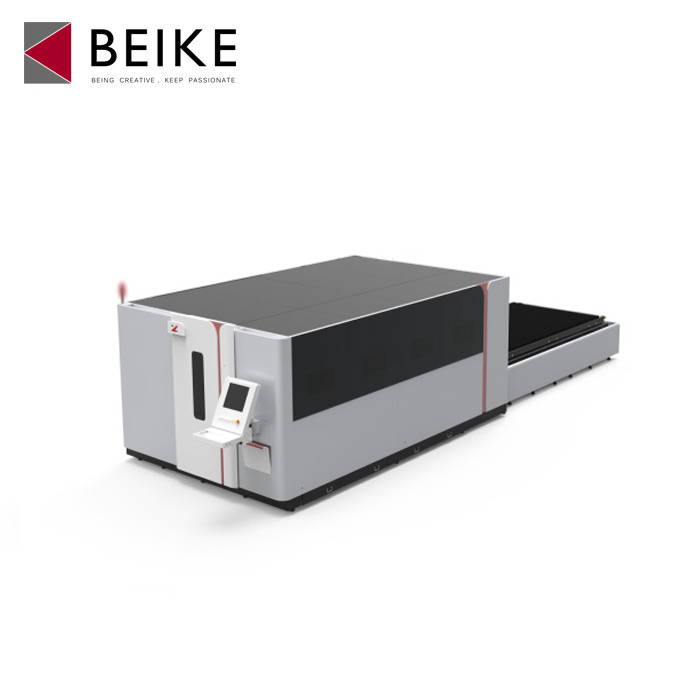

Enclosed Design

Exchange Platform

Welded Bed / Whole Cast Iron Bed / Manu – Marble Bed

IPG or Raycus Laser Source

Laser Power: 1000W – 6000W

Plate & Tube Dual Cutting Use.

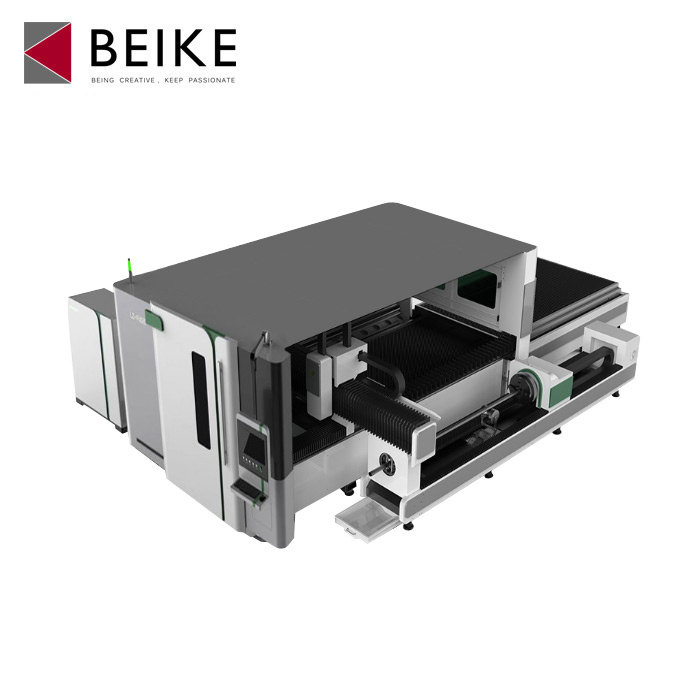

Single Platform

Welded Bed / Whole Cast Iron Bed / Manu – Marble Bed

IPG or Raycus Laser Source

Laser Power: 1000W – 8000W

Plate & Tube Dual Cutting Use.

Exchange Platform

Welded Bed / Whole Cast Iron Bed / Manu – Marble Bed

IPG or Raycus Laser Source

Laser Power: 1000W – 8000W