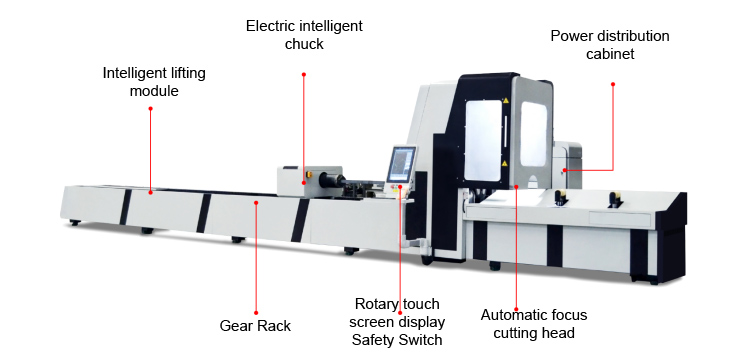

Product Details

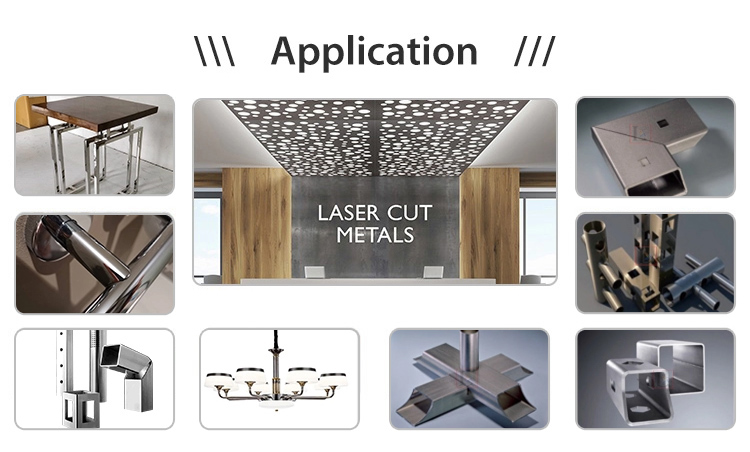

Used for laser cutting round, square tube and other shaped profiles with higher cutting efficiency and less tailstock. It also can be matched with special material tools for working efficiency improvement;

The High efficiency pneumatic chuck tail material surplus can be as low as 250-300mm. Use laser to cut the pipe can replace the traditionally mechanical drilling, milling, sawing, stamping and other machining processes that require different equipment and hard tools, so as to realize the cutting, chamfering, cutting grooves or holes, notches and other possible size and shape features of the complex pipe structure.

| Model | Cutting Length | Cutting Size | Laser Power | Positioning Accuracy | Repositioning Accuracy |

| 6000G | 6000mm |

20-200mm Round Tube 20-220mm Diagonal Length Square Tube |

1000W 1500W 2000W 3000W 4000W 6000W | ±0.03mm | ±0.02mm |

| 9000G | 9000mm | ||||

| 12000G | 12000mm |

Whole machine’s support seat structure

Enhanced blessing force realize heavy - duty pipe clamp machining

Support segmented clamping

Small axial size, can be deep into the inner hole with rear chuck for achieving less waste

Precise internal transmission structure with excellent wearability

Product Advantages

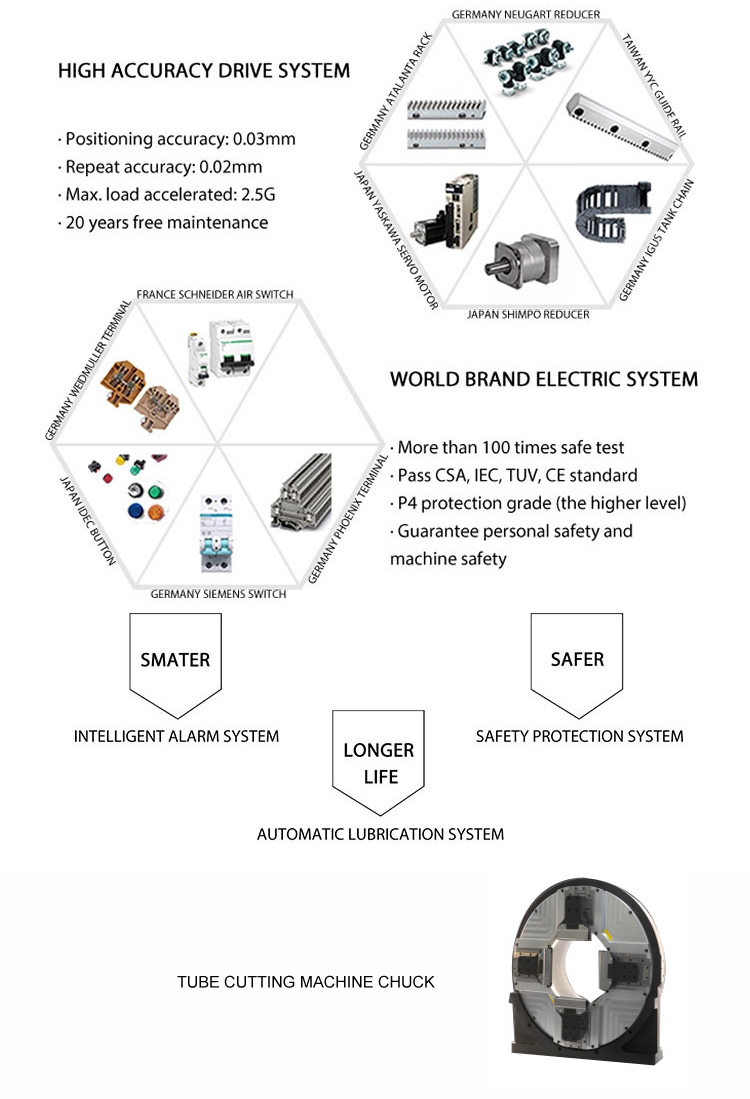

High positioning accuracy: when linear guide rail is used as a linear guide, because the friction mode of linear guide rail is rolling friction, not only the friction coefficient is reduced to 1/50 of the sliding guide, but also the difference between the dynamic friction force and the static friction force becomes very small. Therefore, when the bed is running, there will be no slippage, which can reach the positioning accuracy of μm level

Less wear can assist to maintain the accuracy for a long time: the traditional sliding guidance will inevitably lead to poor movement accuracy of the platform due to greasy countercurrent action, and insufficient lubrication during movement will lead to the wear of the track contact surface, which will seriously affect the accuracy. However, the friction of the rolling guidance is very small, so the machine can maintain the accuracy for a long time

Suitable for high-speed movement and can greatly reduce the driving horsepower of the machine. Due to the linear guide rail movement friction is very small, only require small power to make the bed to run, especially the bed is working for regular round-trip operation, can significantly reduce the power loss of the machine. And because its friction produces small heat, can be suitable for the high-speed operation.

Can simultaneously bear the loading of up, down, left and right direction. Rail movement stability means the guide rail in low speed movement or trace movement does not appear crawling phenomenon performance. The stability is related to the structure of the guide rail, the matching of the auxiliary materials of the guide rail, the lubrication condition, the properties of the lubricant and the stiffness of the driving system of the guide rail. Vibration resistance and stability vibration resistance refer to the ability of the steering rail pair to bear the forced vibration and impact, while stability refers to the performance of no self-excited vibration under given operating conditions. Due to the special beam structure design of linear guide rail, it can bear the load of up and down direction at the same time, unlike the light side load that can be borne by sliding guide in the direction of parallel contact surface, it is easy to cause the machine to run with poor accuracy

Easy assembly and interchangeability. When assembling, only require the assembly surface of the guide rail on the milling or grinding table is cut, and the guide rail and the slide block are fixed on the machine with a specific torque force according to the recommended steps, which can reproduce the high precision during processing. In traditional sliding guidance, the track must be shoveled, which is very time-consuming, and once the accuracy of the machine is not good, it must be shoveled again. The linear guide rail has interchangeability, can replace the slider or guide rail or even the linear guide rail group, the machine can regain the high precision guidance.

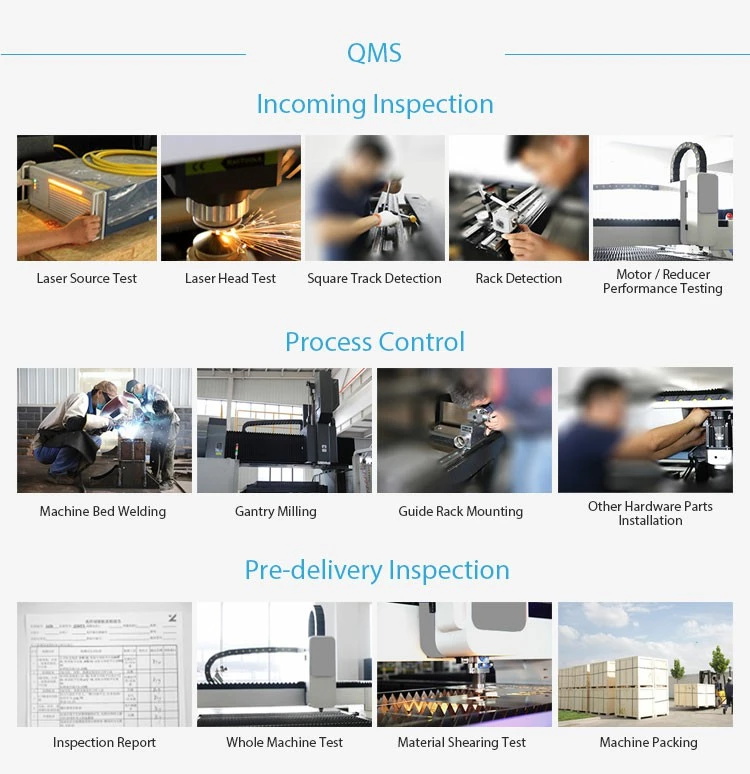

Export standard for Metal Fiber Laser Cutting Machine Laser Cutter:

1-Scratch resistant and anti-static with professional packing film;

2-Anticollision for whole machine with special mould;

3-Waterproof and waterproof with tarpaulin material.

Approved Vendor for International Giants SIEMENS

Member of CLA (China Laser Association)

CNGC (China Weapon Industry Corporation) Laser Equipment Supplier

Annual total export exceeds 15 million US dollars

Professional provider of Wisdom solutions in China.

FAQ

Q1: What can I get the available machine if I don't know anything about laser?

BEIKE Laser will provide the customized application solution for your requirements, just tell us your material, material thickness, worktable and e-mail or WhatsApp ID.

Q2: How to choose the machine that I want?

BEIKE Laser provides information consulting about product, price, technology and industry solutions for customers at any time via network, telephone, email and door to door.

Q3: When I got this machine, but I don’t know how to use it. What should I do?

BEIKE Laser provides free installation and training for users’ technicians, ensures that users can get familiar with operation methods and put machines into use as soon as possible.

Q4: If some problems happen to this machine, what should I do?

BEIKE Laser provides 3 years warranty and lifetime maintenance. Free repair for mechanical failure and parts damage (no human factors and force majeure factors) under warranty (replacement parts except wearing parts are provided by BEIKE Laser are free of charge). Charging at cost when out of warranty.

Related Products

Inquiry