Product Details

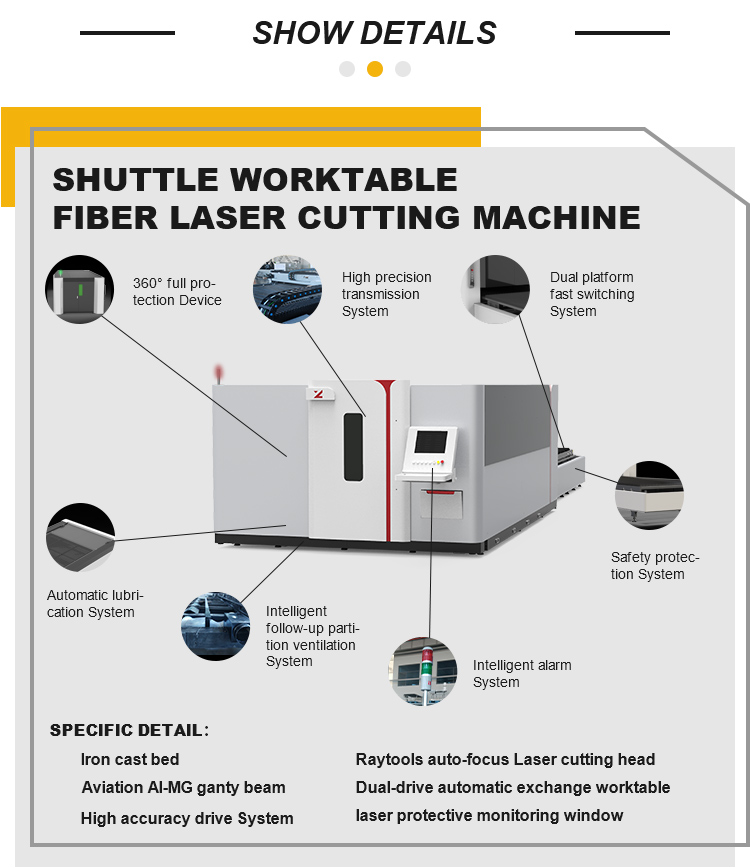

The upgraded guide design can largely assist to reduce the horizontal friction and wear & tear result from cutting process, the automatic lubrication system also makes the machine maintenance work more convenient and get the laser cutting precision improved and service life extended, also with the improvement of backside bed‘s hydraulic lifting system, it makes the exchange process much more stable and fast.

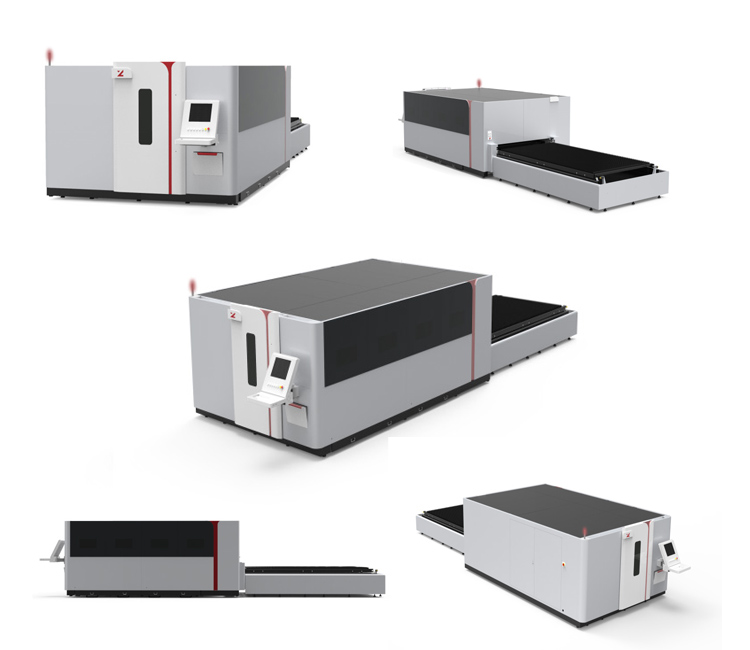

| Model | Cutting Area | Laser Power | Bed |

| X3015 | 3020*1520 | 1000W 1500W 2000W 3000W 4000W 6000W | Cast Iron Bed/Hydraulic Lifting |

| X4015 | 4020*1520 | ||

| X4020 | 4020*2050 | ||

| X6020 | 6020*2020 | ||

| X6025 | 6020*2520 |

> Higher performance, lower consumption.

The working efficiency of fiber laser cutting machine is 10 times that of the same power co2 laser cutting machine and 5 times that of the YAG laser cutting machine. The Energy consumption is only 1/6 of the YAG laser cutting machine.

> Higher photoelectric conversion rate.

More stable, the module-optimized photoelectric conversion rate can reach 30%, a greater increase from the average of 20%-25%. The lifetime of laser source is over 10,0000 hours with full power high speed cutting work.

> Higher cutting precision.

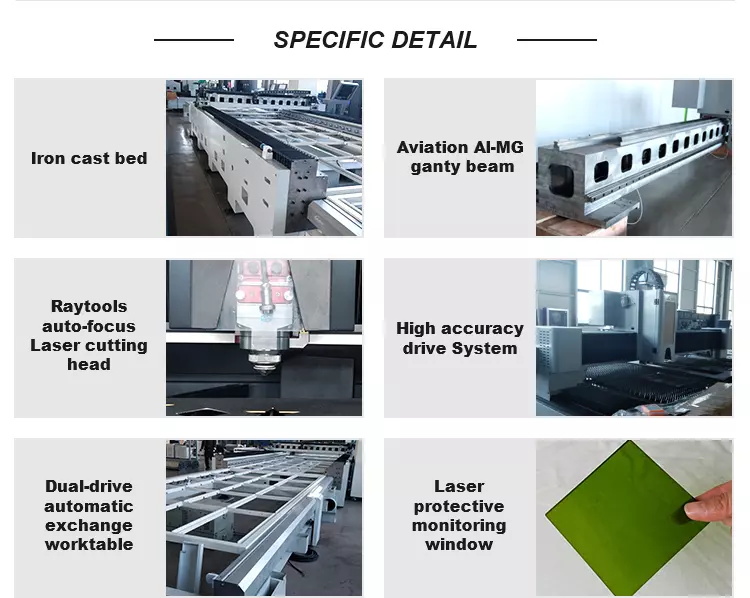

Higher cutting speed. Micron-level cutting, gantry-type double-drive structure, HT250 cast iron bed, third-generation aviation aluminum magnesium alloy beam, world-class drive system, autofocus laser cutting head, can withstand 2.5G acceleration.

> Easy to operate, designed with ergonomic standard.

Professional control and nest software, easy to learn and operate like drving the car, so long as you comply with the guide. Integrated control cabinet, all machine body are designed according to Germany DIN terms.

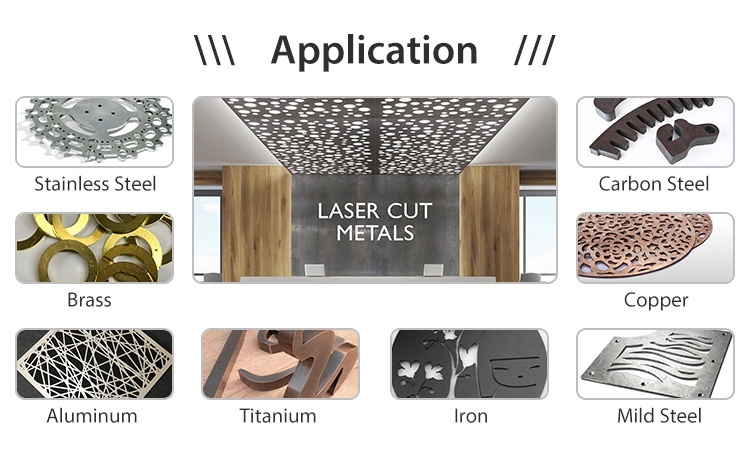

The all covered protective fiber laser cutting machine is suitable for stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium and other metal plate products.

It is widely used in advertising, high pressure/low voltage electrical cabinet production, textile machinery accessories, kitchen appliances, cars, machinery, elevators, electrical accessories, spring coil pieces, metro line parts and other industries.

Export standard for Metal Fiber Laser Cutting Machine Laser Cutter:

1-Scratch resistant and anti-static with professional packing film;

2-Anticollision for whole machine with special mould;

3-Waterproof and waterproof with tarpaulin material.

Approved Vendor for International Giants SIEMENS

Member of CLA (China Laser Association)

CNGC (China Weapon Industry Corporation) Laser Equipment Supplier

Annual total export exceeds 15 million US dollars

Professional provider of Wisdom solutions in China.

FAQ

Q1: What can I get the available machine if I don't know anything about laser?

BEIKE Laser will provide the customized application solution for your requirements, just tell us your material, material thickness, worktable and e-mail or WhatsApp ID.

Q2: How to choose the machine that I want?

BEIKE Laser provides information consulting about product, price, technology and industry solutions for customers at any time via network, telephone, email and door to door.

Q3: When I got this machine, but I don’t know how to use it. What should I do?

BEIKE Laser provides free installation and training for users’ technicians, ensures that users can get familiar with operation methods and put machines into use as soon as possible.

Q4: If some problems happen to this machine, what should I do?

BEIKE Laser provides 3 years warranty and lifetime maintenance. Free repair for mechanical failure and parts damage (no human factors and force majeure factors) under warranty (replacement parts except wearing parts are provided by BEIKE Laser are free of charge). Charging at cost when out of warranty.

Related Products

Inquiry