Product Details

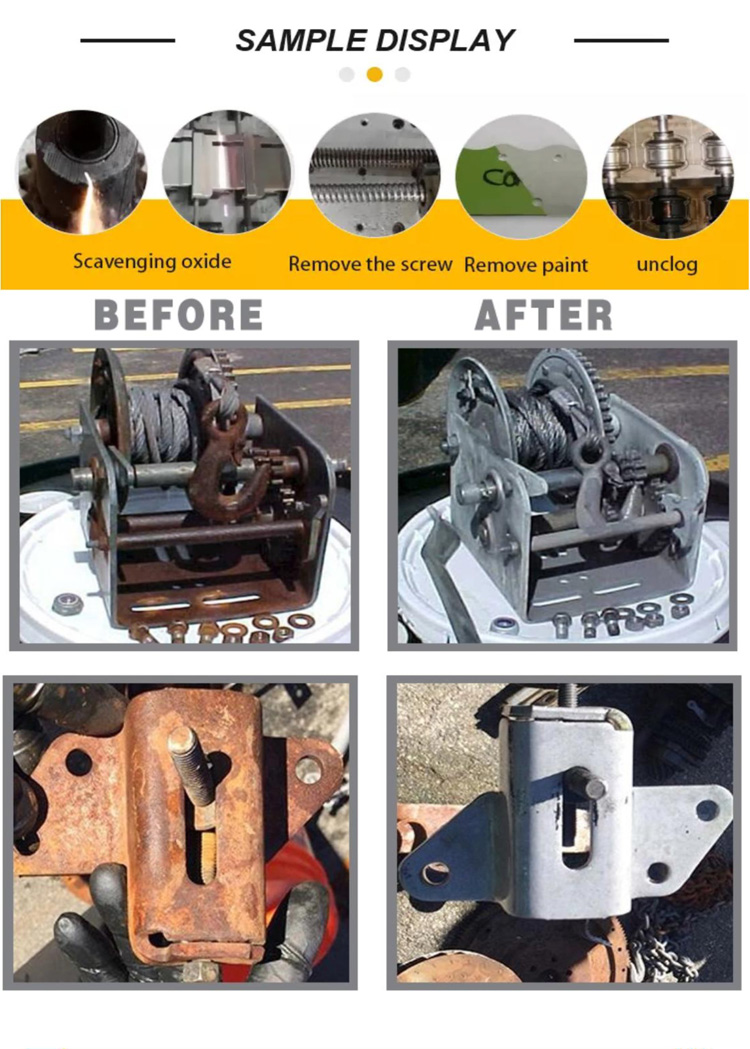

Examples of laser cleaning applications include:

• Rust removal

• Mold cleaning

• Paint stripping

• Baking plate cleaning

• Heat Seal Die cleaning

• Art or antique restoration

• and many more

Advantages of Laser Cleaning:

• Precise Cleaning Area– small spot size of focused laser energy allows for fine control of cleaning locations.

• Non-Contact – no mechanical contact to cause unnecessary wear.

• No Consumables – laser cleaning eliminates the need for consumables such as chemicals or replacement cleaning tools.

• Flexible Integration – Laser cleaning systems can stand alone or be integrated into a production line.

|

Model |

BK-BLC50 |

|

Laser power |

50W |

|

Laser wavelength |

1064nm |

|

Cooling method |

Air cooling |

|

Power |

400W |

|

Scan width |

10-50 |

|

Optional matching |

Hand held / Automation |

|

Working environment temperature |

5-40℃ |

|

Length of light |

3 meters (optional 5 meters) |

|

Power Supply |

220V-50/60Hz |

|

Laser grade |

4 |

|

Control system |

Autonomous research and development control system |

|

Cleaning mode |

Equipment comes with a variety of patterns, free choice processing (linear, round type) |

TYPICAL CLEANING EFFICIENCY

|

Laser Power |

50W |

|

|

Peak Power |

15kW |

|

|

Beam Quality |

1.3-1.8 |

|

|

Cleaning Efficiency |

Rusting(20um) |

2.0㎡/h |

|

Oil Contamination(20um) |

2.5㎡/h |

|

|

Aluminum Oxide Film |

|

|

|

Rubber Residues |

4m2/h - 5m2/h |

|

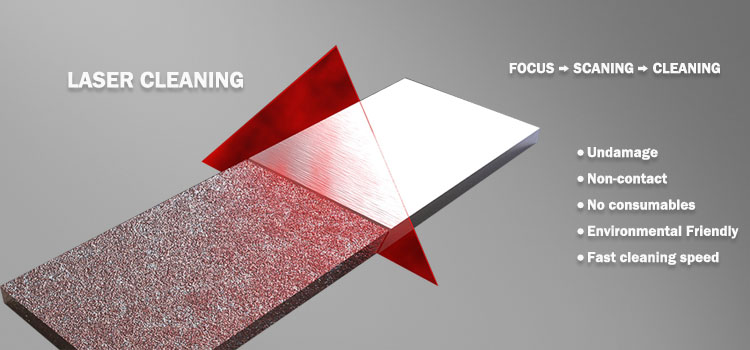

Method of Laser Cleaning:

Laser energy is focused onto the part and steered through the cleaning area using a galvanometer. The high energy density beam reacts with the surface to remove the unwanted coating or layer. The laser cleaning process works most efficiently when the substance being removed has high absorption in a specific wavelength range of laser energy and the underlying substrate is reflective in this same range. This relative difference of absorption causes the unwanted material to heat up quickly and ablate from the surface leaving the substrate unaffected. A fume extraction system is used in conjunction with the laser to remove the airborne ablated material in a clean and controlled manner.

Approved Vendor for International Giants SIEMENS

Member of CLA ( China Laser Association)

CNGC(China Weapon Industry Corporation)Laser Equipment Supplier

Serving more than 150 countries and regions,

Annual total export exceeds 15 million US dollars

Professional provider of Wisdom solutions in China.

FAQ

Q1: What can I get the available machine if I don't know anything about laser?

BEIKE Laser will provide the customized application solution for your requirements, just tell us your cleaning requirements, then we shall feedback you with a good solution very much quickly.

Q2: Are you manufacturer or trader?

BEIKE Laser is the direct manufacturer with professional workers that operating with laser machine for many years. We not only provide you a suitable tool, but also work to help you produce better products and gain greater market competitiveness.

Q3: When I got this machine, but I don’t know how to use it. What should I do?

BEIKE Laser provides free installation and training for users’ technicians, ensures that users can get familiar with operation methods and put machines into use as soon as possible.

Q4: If some problems happen to this machine,what should I do?

BEIKE Laser provides 3 years warranty and lifetime maintenance for the laser cleaning machines. Free repair for mechanical failure and parts damage (no human factors and force majeure factors) under warranty (replacement parts except wearing parts are provided by BEIKE Laser are free of charge). Charging at cost when out of warranty.

Related Products

Inquiry