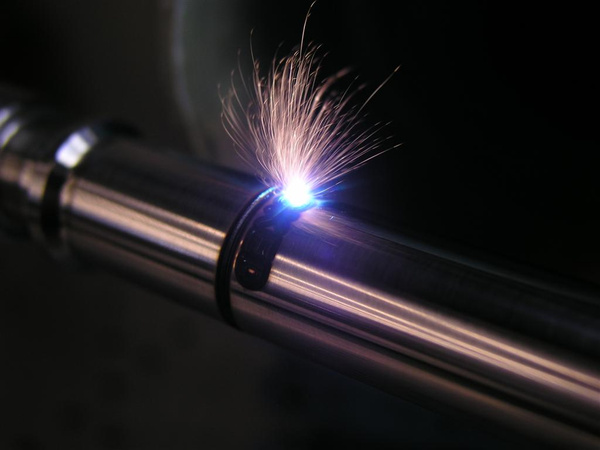

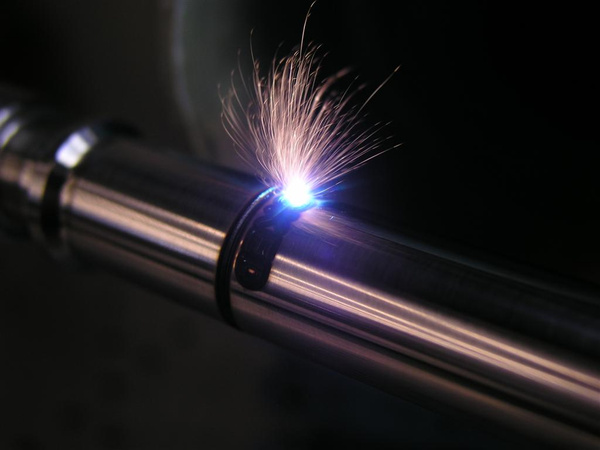

At present, with the rapid development of laser technology, laser technology in the field of industrial applications is more and more in-depth, in the processing of many aspects of the laser we can see the application of the figure, it can be said that today's laser technology has become the industry now An indispensable part.,especially in the field of marking today, due to the limitations of traditional marking technology, marking and processing of certain industrial areas is subject to certain obstacles, it is difficult to achieve the needs of industrial processing. In order to be able to effectively solve this problem, now more and more areas will look to the current laser marking industry, especially in the field of precision machining. As the laser marking is different from the traditional markings, the laser marking is a marking method that uses a laser with a high energy density to locally irradiate the workpiece, vaporize the surface material, or cause a color change, thereby leaving a permanent marking method. Compared to traditional corrosion, EDM, mechanical scribing, printing and other traditional processing methods laser marking has its own unique craft.

1. The use of laser marking, and there is no work force between the workpiece, with no contact, no cutting force, the advantages of small heat, to ensure the original accuracy of the workpiece. At the same time, the adaptability of the material is wide, you can play in a variety of materials on the surface of a very fine mark and durability is very good;

2. Laser space control and time control is very good, the processing of the material, shape, size and processing environment of the degree of freedom are very large, especially suitable for automatic processing and special surface processing, and flexible processing methods can also to meet the requirements of industrial mass production;

3. Laser scribe fine, the line can reach the order of microns, the use of laser marking technology to create the mark imitation and changes are very difficult, the product is extremely important;

4. Laser processing system and computer numerical control technology can be combined to form a highly efficient automated processing equipment, you can play a variety of texts, symbols and patterns, easy to use software design mark pattern, change the mark content, to meet the modern production of high efficiency, fast pace requirements ;

5. Laser processing is not a source of pollution, is a clean and pollution-free high-environmental processing technology.

It can be said that the emergence of laser marking machine is undoubtedly another leap in marking processing, great improvement and make up for the lack of traditional marking processing, rich process characteristics, but also for the current mark processing provides a rich show effect. In the current laser marking has been applied to electronic components, integrated circuits (IC), electrical appliances, mobile communications, metal products, tool accessories, precision instruments, glasses watches and clocks, jewelry accessories, auto parts, plastic keys, building materials, PVC pipe many fields.